Business Introduction

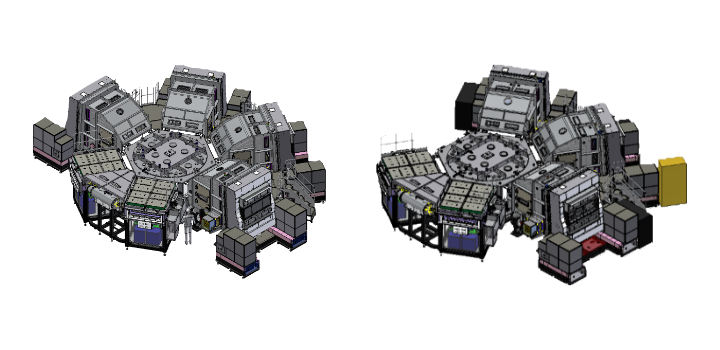

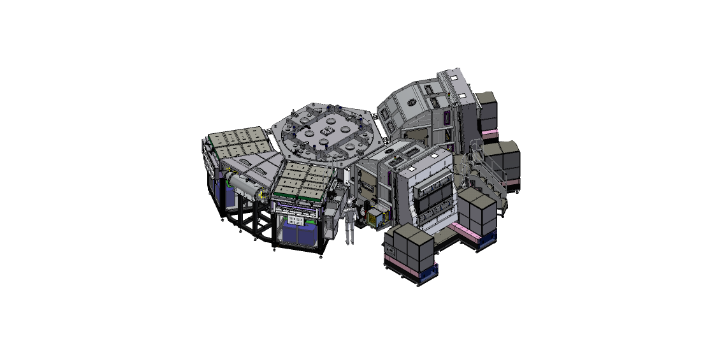

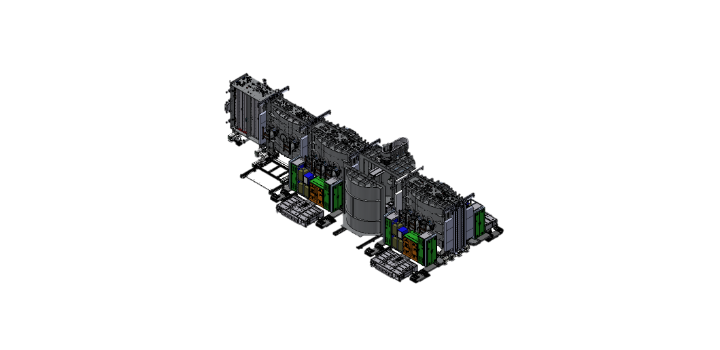

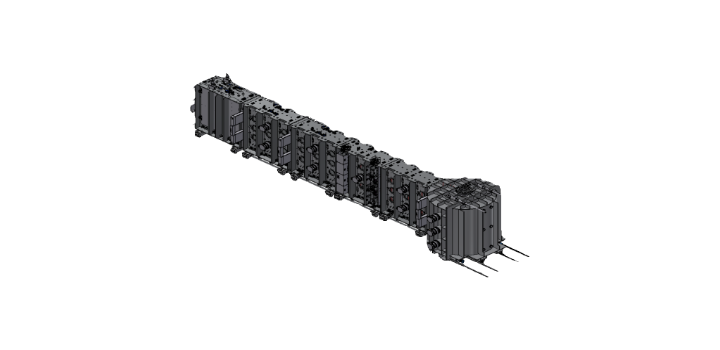

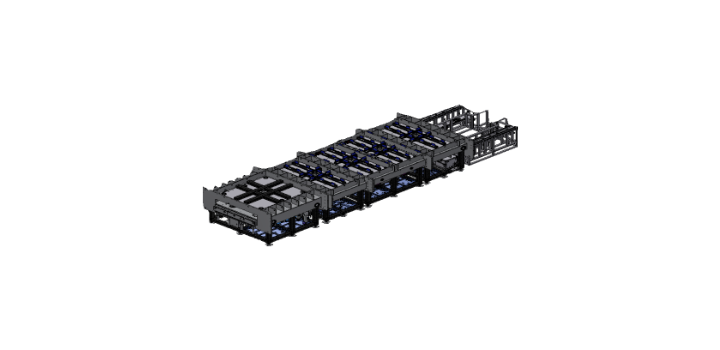

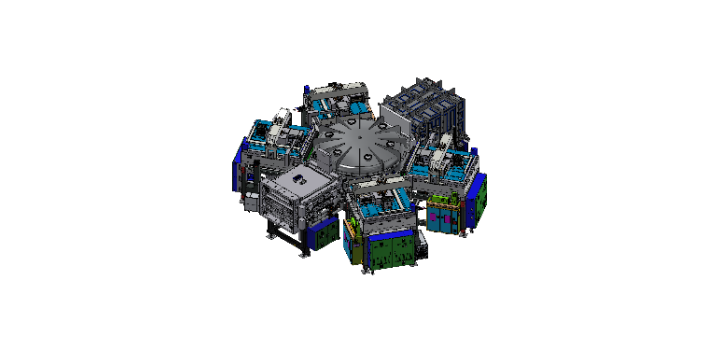

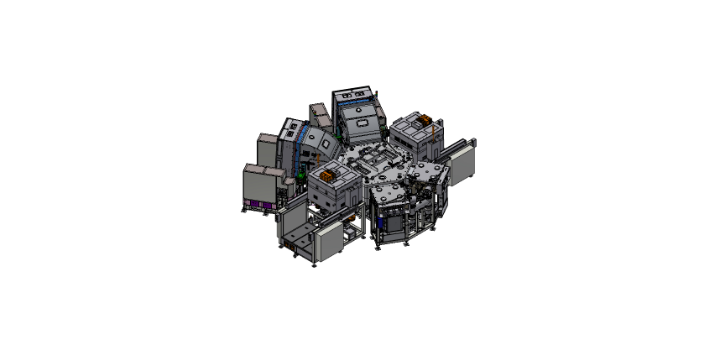

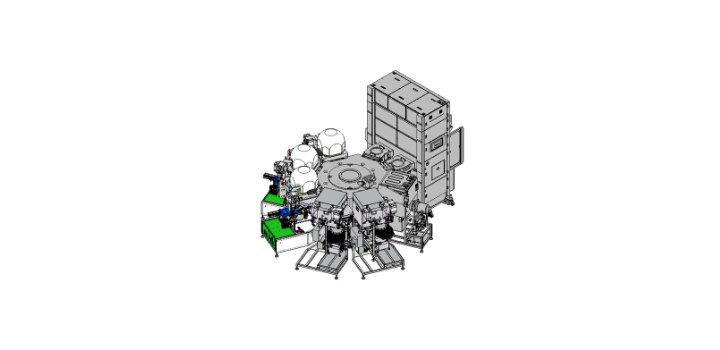

H&iruja possesses advanced deposition technology essential for the manufacturing of next-generation displays and semiconductors

Business Introduction

H&iruja possesses advanced deposition technology essential for the

manufacturing of next-generation displays and semiconductors